At some point, most of us will have travelled in or out of the UK by plane or ship. In either case, moving through a departure or arrival lounge when pressed for time can be stressful.

As a result, airport and marine port operators invest heavily in their building’s infrastructure to ensure that passenger convenience and safety is always at the forefront of any maintenance or refurbishment planning.

Working as subcontractors to the principal lift service provider, we were asked to estimate for the modernisation of two passenger lifts located in a busy departure and arrivals area.

The hydraulic lifts in question are both high usage units so experience sustained use during peak transit periods. As a result, and as part of the modernisation, Hydratec replaced the worn landing buttons with new tactile buttons, landing and car door operators and the cars’ ceilings.

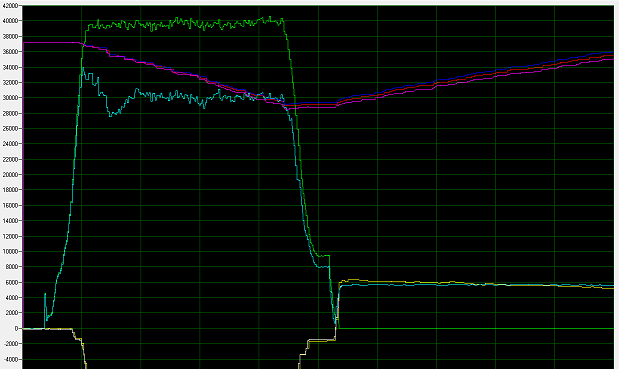

The hydraulic and in-shaft part of the modernisation included two fully A3 compliant Hydratec ecosmart+™ systems, utilising Bucher iValves and Hydratec-specific Lester Controls EN81-20 Almega II lift controllers. Additionally, within the shaft, Hydratec installed APS (CEDES) Absolute Positioning Systems and, as part of the modernisation, Hydratec also undertook a full rewire of each lift system.

As a result of the duty requirements of each lift, larger hydraulic oil tanks were required, which resulted in the tanks and controllers being installed adjacent to each other rather than in Hydratec smart™ cabinets.

Download PDF version here.

Hydratec undertook a modernisation of two passenger lifts located at a busy infrastructure’s departure and arrivals area.

Hydratec undertook a modernisation of two passenger lifts located at a busy infrastructure’s departure and arrivals area.

Working alongside the lift service provider for a hospital in Surrey, Hydratec has recently completed a Bucher SUPERCAPS installation on the lift in operation there.

Working alongside the lift service provider for a hospital in Surrey, Hydratec has recently completed a Bucher SUPERCAPS installation on the lift in operation there.