News

30 Year Anniversary

This year, we are proud to be celebrating a significant milestone in the history of our company—our 30th anniversary! It is with great pride that we reflect on the journey of Hydratec Lift Services, from its humble beginnings to becoming one of the leading hydraulic lift repair and modernisation companies in the UK. Join us as we take a trip down memory lane and explore what we have achieved in the 30 years.

A legacy of exceptional customer service:

Over the past three decades, our company has continuously strived to provide outstanding customer service in hydraulic lift repair and modernisation. Our unwavering commitment to customer satisfaction has been the driving force behind our success. From the very beginning, we set out to have customer satisfaction and honesty at the core of our business and that remains the same today.

Building Strong Partnerships:

One of the key factors behind our enduring success has been the long-standing relationships we have built with our clients. We recognize that our customers are at the heart of our business, and their trust and support have been instrumental in our growth. We work closely with our customers and industry professionals to understand their unique needs and challenges.

By fostering open lines of communication and delivering tailor-made solutions, we have been able to create sustainable partnerships that go beyond mere transactions. Our commitment to providing exceptional customer service and ongoing support has cemented our reputation as a trusted partner.

Our experience and close working relationships with our customers and suppliers means we have successfully completed some very complex, difficult projects over the last 30 years.

Embracing Sustainability:

As the world became more conscious of environmental concerns, we recognized the importance of sustainable practices in the hydraulic lift industry. Our commitment to environmental stewardship led us to develop eco-friendly solutions that not only meet regulatory standards but also exceed them. We have also been ISO14001:2015 accredited for many years.

By incorporating energy-efficient technologies, optimizing resource usage, and promoting recycling and waste reduction, we have actively contributed to building a greener future. We are proud to have played our part in reducing carbon emissions and ensuring that our hydraulic lift modernisation solutions are environmentally responsible.

Looking Ahead:

As we celebrate our 30th anniversary, we also look to the future with anticipation and excitement. We remain committed to our core values of honesty, customer satisfaction, and sustainability. The next chapter in our journey will see us continuing to adapt to the evolving needs of our customers.

A Big Thankyou

We would be nothing without our employees, partners, and clients who have been at the core of our success. It is their unwavering support and confidence in Hydratec that has allowed us to achieve this significant milestone and propel our company forward.

And finally

As we raise a toast to 30 years of success, we express our heartfelt gratitude to everyone who has been part of this incredible journey. We are immensely proud of our accomplishments and the positive impact we hope we have made on the industry.

With your continued support, we are confident that the next 30 years will be even more remarkable as we navigate the ever-changing challenges of hydraulic lift modernisation.

Thank you for being part of our story. Here’s to celebrating the past and embracing the future.

Elevating Service Excellence: Introducing Routine Maintenance for Hydraulic Lifts

Introduction:

Welcome! We are thrilled to announce an exciting expansion of our sub-contract services here at Hydratec Lift Services. As a trusted partner, we are constantly seeking new ways to better serve our valued clients. With that in mind, we are delighted to introduce our comprehensive routine maintenance program for hydraulic lifts. Join us as we explore the benefits and importance of regular maintenance and how it contributes to the longevity and performance of hydraulic lift systems.

The Importance of Routine Maintenance:

Hydraulic lifts are vital components of numerous buildings, providing safe and efficient vertical transportation. Just like any other system, regular maintenance is essential to ensure optimal performance, safety, and longevity. Routine maintenance plays a crucial role in preventing issues before they escalate into costly repairs and disruptions.

Expanding Our Services:

Recognizing the value of routine maintenance, we are pleased to expand our service offerings to include comprehensive maintenance programs for hydraulic lifts. Our team of highly skilled technicians and engineers can now provide proactive inspections, thorough servicing, and preventive maintenance to keep your hydraulic lift in prime condition.

Benefits of Routine Maintenance:

Enhanced Safety: Safety is our top priority. Regular maintenance allows us to identify and address potential safety hazards, ensuring that your hydraulic lift meets or exceeds industry safety standards. We conduct thorough inspections of critical components, including control systems, safety devices, and mechanical parts, to ensure optimal functionality and mitigate risks.

Extended Lifespan: By proactively maintaining your hydraulic lift, we can identify and rectify minor issues before they escalate into major problems. This approach helps to prevent breakdowns, extends the lifespan of your lift, protects your investment and reduces the need for costly repairs or premature replacements.

Improved Performance: Routine maintenance keeps your hydraulic lift operating at peak performance. We lubricate moving parts, check fluid levels, adjust hydraulic systems, and perform other necessary tasks to optimize lift efficiency and smooth operation. This results in improved passenger experience, reduced downtime, and increased productivity.

Cost Savings: Investing in routine maintenance can lead to significant cost savings in the long run. By identifying and addressing potential issues early on, we help you avoid expensive breakdowns and emergency repairs. Additionally, a well-maintained hydraulic lift operates more efficiently, leading to reduced energy consumption and lower utility bills.

Compliance with Regulations: Regular maintenance ensures that your hydraulic lift remains compliant with relevant safety regulations and building codes. We stay updated with the latest industry standards and conduct inspections accordingly, providing you with the assurance that your lift meets all required guidelines.

Exceptional Service You Can Trust:

Our expanded routine maintenance program is backed by our unwavering commitment to exceptional service. We understand that every client’s needs are unique, which is why we tailor our maintenance programs to suit your specific requirements. Our experienced technicians will work closely with you to develop a maintenance schedule that aligns with your budget, building usage, and compliance obligations.

Conclusion:

Here at Hydratec Lift Services we are excited to offer our valued clients an expanded range of services, including comprehensive routine maintenance programs for hydraulic lifts. By investing in regular maintenance, you can ensure the safety, longevity, and optimal performance of your lift system.

Trust our team of experts to conduct thorough inspections, perform necessary servicing, and deliver preventive maintenance that keeps your hydraulic lift operating at its best. Contact us today to learn more about our routine maintenance programs and experience the difference our exceptional service can make for your hydraulic lift. Elevate your vertical transportation experience with our comprehensive maintenance service!

Christmas Opening Hours 2022/23

Hydratec would like to wish all our customers Merry Christmas and a Happy New Year! We would like to take this opportunity to thank you all for your business this year. Our festive opening hours are as follows:-

Monday 19th December 8.00 am – 6.00 pm

Tuesday 20th December 8.00 am – 6.00 pm

Wednesday 21st December 8.00 am – 6.00 pm

Thursday 22nd December 8.00 am – 6.00 pm

Friday 23rd December 8.00 am to 1.00 pm

Monday 26th December CLOSED

Tuesday 27th December CLOSED

Wednesday 28th December CLOSED

Thursday 29th December CLOSED

Friday 30th December CLOSED

Monday 2nd January CLOSED

Tuesday 3rd January 8.00am – 6.00 pm

Heywood Office Closure

Hydratec Lift Services would like to inform all of our customers that due to the difficulties of the local recruitment of skilled staff in the North of England, we have reluctantly closed our Heywood office.

The decision was not taken lightly as we have worked hard to provide the same level of excellent customer service that we deliver in the South of England, from our Yateley office. We apologise to those of our customers for this office closure who have been working with our Heywood team and hope you understand our reasons and objectives of only providing the very best of service at all times.

Our office at Yateley continues at full strength operating as usual, offering a nationwide service for the supply of equipment and spares. Please do not hesitate to contact the team at Yateley if you have any questions and we can offer any further assistance.

Bucher REGEN systems installed in the Palace of Westminster

Working on behalf of our client, Hydratec have installed three Bucher REGEN systems within the Palace of Westminster.

One of the lifts was using a Bucher BERIPAC™ system, that was to be converted to a conventional 2:1. For those of you not familiar with the BERIPAC, this system used a pulling cylinder rather than a conventional cylinder. The car sling, roping system, pulley and cylinder were converted and a new motor room was formed to house the drive unit and controller. The accumulators were removed and the REGEN unit installed.

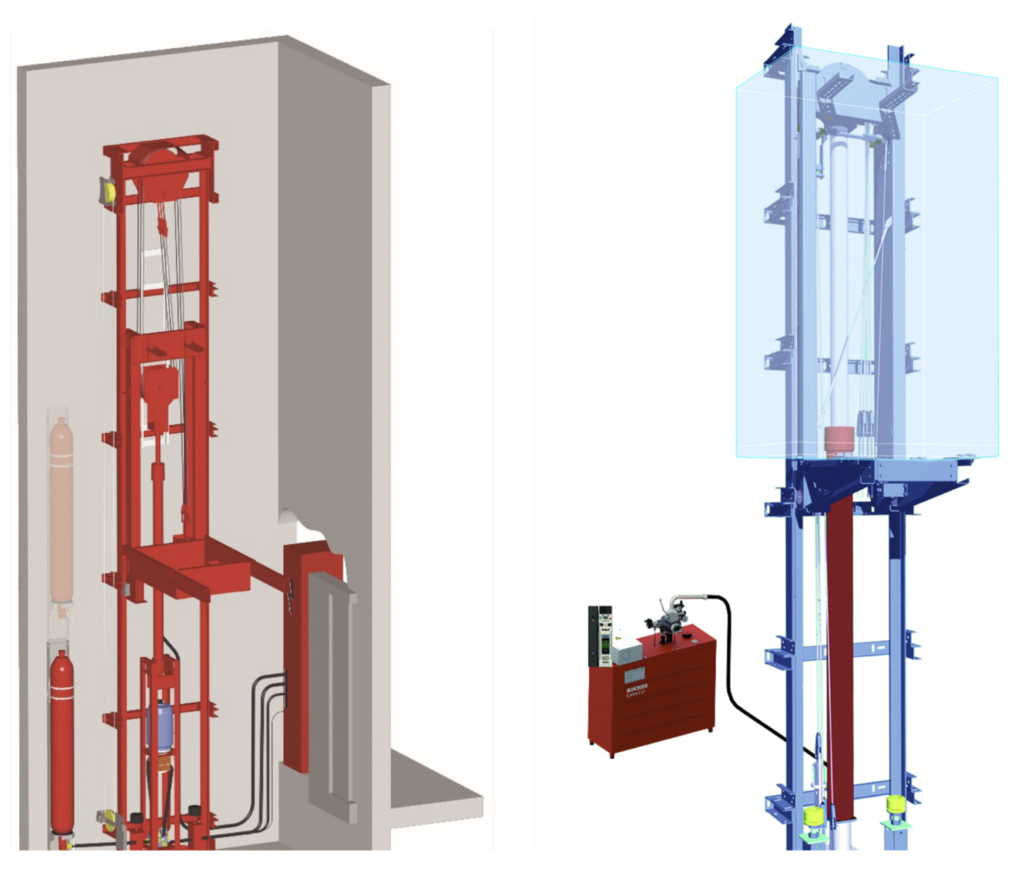

Below are some diagrams explaining the conversion process. If you would like more information on converting the BERIPAC system, please get in touch.

Bespoke Solution for a Critical Lift in a London Landmark Building

Hydratec were asked to provide a bespoke solution for a critical lift located in a well-known London landmark building. The lift had been suffering from ongoing reliability issues. It had been originally supplied with two tank units, the tank units were linked to allow one tank to take over in the event of failure of the other. The changeover system was very complicated and our brief was to replace the tank units and make the changeover very simple.

We achieved this by using a twin Bucher Hydraulics LRV power unit with twin A3 valves and a bespoke Lester Control Systems Ltd control system. The whole system can now be swapped from tank to tank with the use of just one key switch, irrespective of lift position. Our team carried out the modernisation on behalf of one of our customers and the client is very pleased with the result.

If you need any bespoke hydraulic solutions we are here to help; our next ‘off the wall’ project is a hydraulically-operated, counterbalanced moving wall in a listed building in London.

2-Tonne 5-Storey Full Lift Modernisation Programme Complete

Hydratec engineers completed the full modernisation programme of a 2-tonne 5-storey lift, at one of the largest UK sewage treatment plants

A tricky job to undertake at the best of times it was made particularly difficult due to the hot weather over last summer, We were very pleased to hear how happy the client was with the final results – so much so, that following a safety audit they considered us the best contractor they had ever had on-site which is high praise indeed considering the stringent safety standards in force.

First Installation of smart with Digital Advanced Controller

We are pleased to announce that, following a request from one of our customers, the first smart® system with a Digital Advanced Control controller has been installed.

Our customer is very pleased with the ease of installation of the full plug and play solution. It was a very quick and easy installation, and we have a very happy client.

Installation of a Bucher Hydraulics Saturn Beta iValve Power Unit

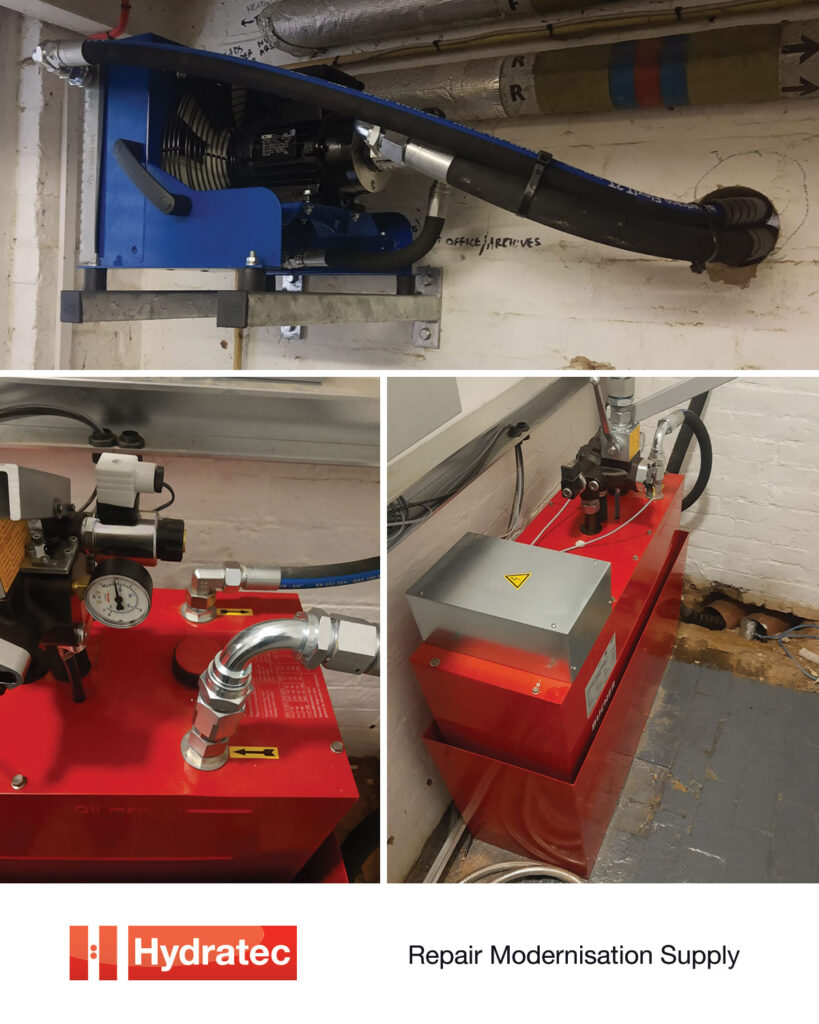

Working on behalf of one of our multi-national customers, we have installed another Bucher Hydraulics Saturn Beta iValve power unit. The pictures show the install part way through the modernisation.

An oil cooler was requested to comply with the specification. A difficult hose run under the floor (in excess of 23 metres), and in 4 wire hose! Not the easiest to get through but we did it.